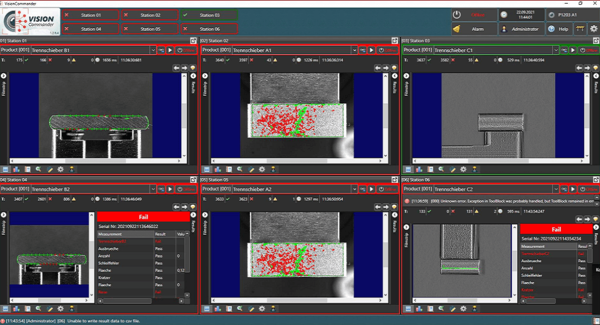

Inspection of Sealing Surfaces

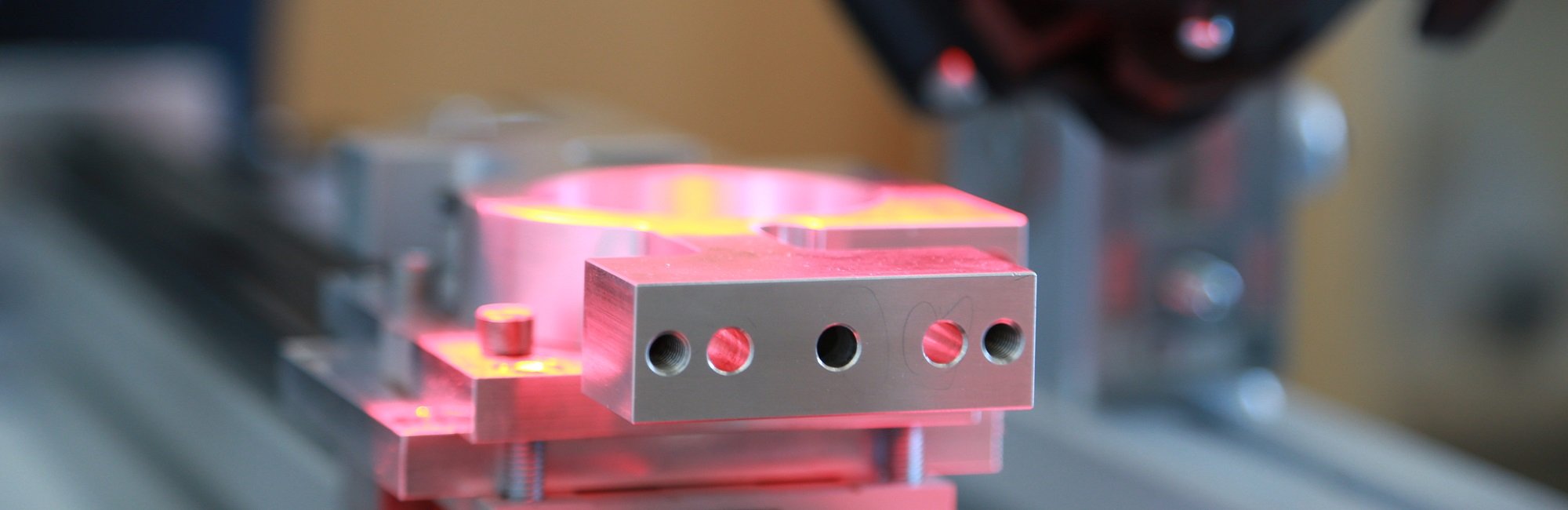

To inspect carbide sealing surfaces, we use a shape-from-shading setup with four illumination directions to detect function-impacting defects such as chipping, scratches, or cracks on surfaces. The setup produces a homogeneous gray-scale image that reproduces the highs and lows of the surface but removes texture.

.gif?width=446&height=262&name=ShapeFromShading_Ring%20(820%20x%20710%20px).gif)