Precise

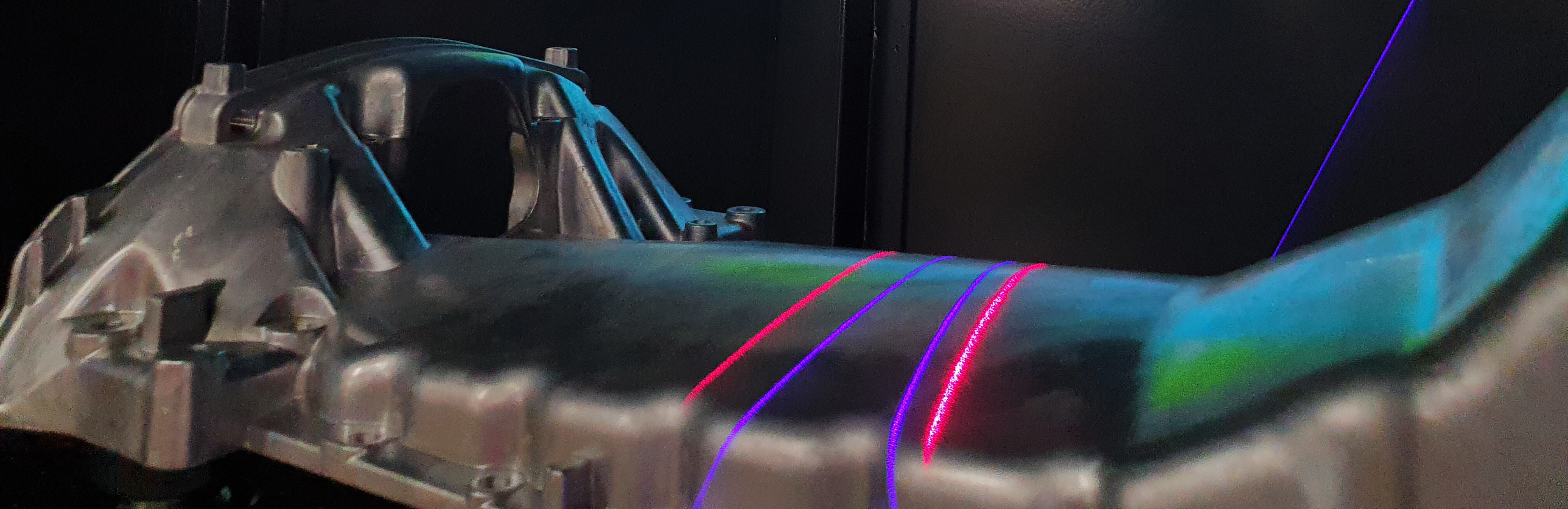

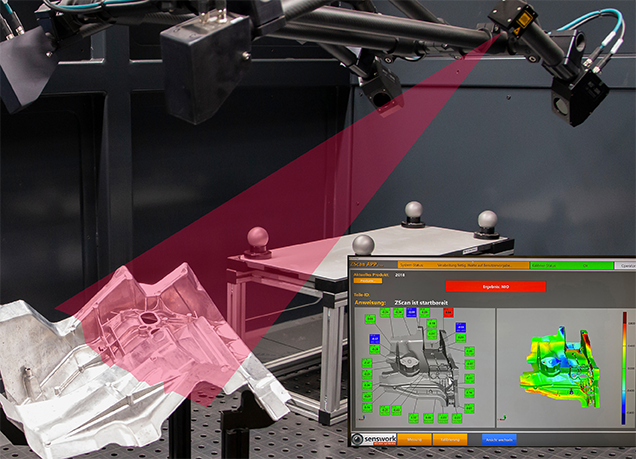

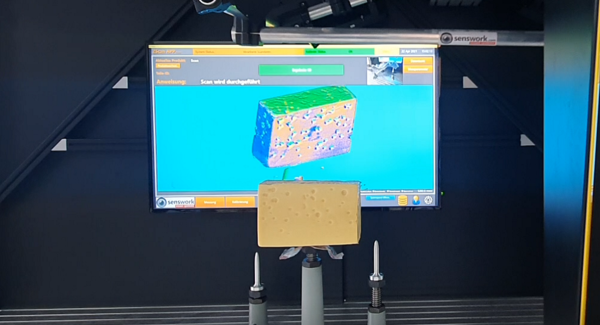

3D MeasurementUp to 8 laser scanners scan the measurement volume from different perspectives and generate a high-resolution 3D data set with up to 20 million measurement points.

Measuring and testing in seconds

High-resolution and seamless 3D scanning of large and geometrically complex parts, automated 3D measurement and inspection. In seconds. Directly in production. This is what ZScan® makes possible.

With the ZScan® 3D measuring system, the dimensional accuracy of large and complex objects can be checked directly in the production process. In a matter of seconds, a part is scanned and compared with its CAD model in 3D. Without pre-treatment of the surfaces. A valid IO inspection of each individual part is therefore possible within seconds, without any need for post-testing in the measuring room. Another advantage: ZScan® can be loaded with parts manually or automatically.

Delivers precise measurement and inspection in seconds

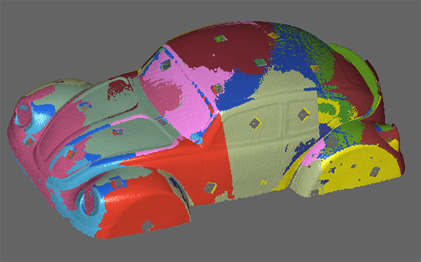

Thanks to a free spatial arrangement, several laser triangulation sensors detect parts, such as aluminum die castings from the automotive industry, almost shadow-free. Based on this, the associated VisionCommander 3D measuring software measures the parts within a few seconds and supports all common alignment methods such as RPS alignment, 3-2-1 alignment or Bestfit. In addition, a direct false color comparison to the CAD model is possible - of course also within seconds.

Precise

3D MeasurementUp to 8 laser scanners scan the measurement volume from different perspectives and generate a high-resolution 3D data set with up to 20 million measurement points.

One System for All Parts

FlexibilityWith ZScan®, many different parts can be inspected without the need for a complex fixture. This can significantly accelerate the setup time for changing parts.

Automated or Manual

Inline MeasurementThanks to high robustness, ZScan® can be used directly on the production line. With manual or automated placement, as required.

Seamless 3D Scan

More Measurement PointsZScan® detects undercuts and shadow areas. Not only individual measuring points, but the entire part is compared to the CAD drawing.

Improve informative value

Take advantage of the potential

Upstream or downstream production can be easily optimized with the measurement data generated by ZScan®. The measurement data can be:

Examples of how you can benefit from the ZScan® 3D measurement system in your industry

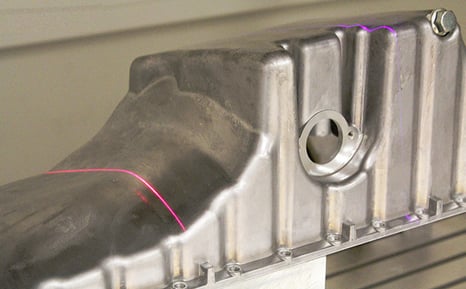

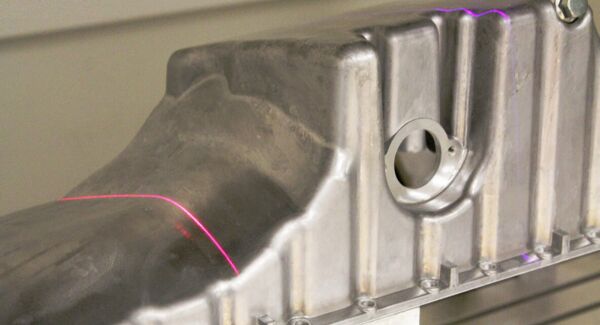

Die-Cast Aluminum

3D Inspection | Automotive

Die-Cast Aluminum

3D Inspection | Automotive

Stamped & Bent Parts

3D Inspection | Automotive

Stamped & Bent Parts

3D Inspection | Automotive

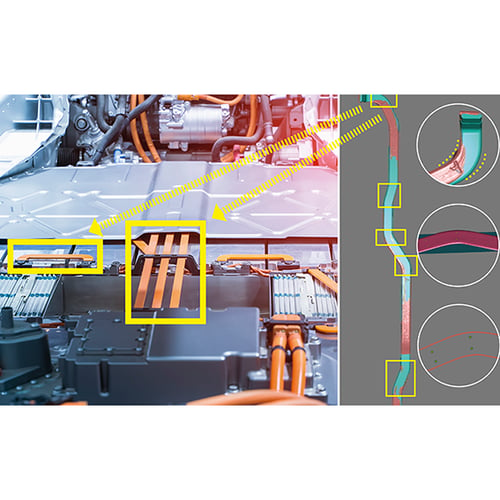

Busbars

3D Inspection | Automotive

Busbars

3D Inspection | Automotive

Lumber

3D Inspection | Wood

Lumber

3D Inspection | Wood

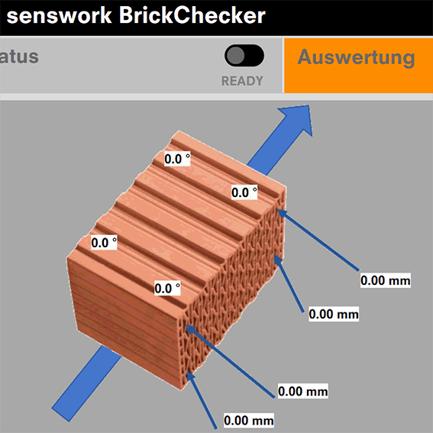

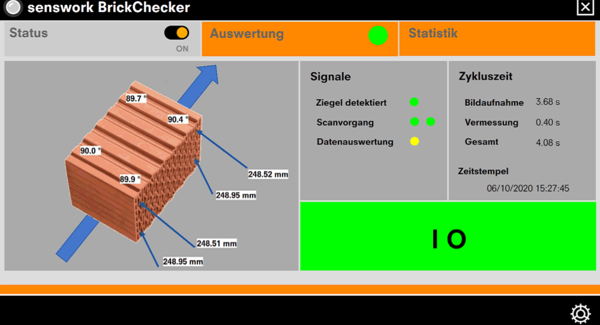

Clay Bricks

3D Inspection | Construction

Clay Bricks

3D Inspection | Construction

Food

3D Inspection | Food & Beverage

Food

3D Inspection | Food & Beverage

ZScan® convinces with many unique features

Rainer Obergrußberger

CEO at senswork GmbH

We experience ZScan® as a game changer in production-related measurement technology. Customers are enthusiastic about the immense time savings, as measurements in the measuring room are no longer necessary with ZScan®.“

Rainer Obergrußberger

CEO at senswork GmbH

For large parts

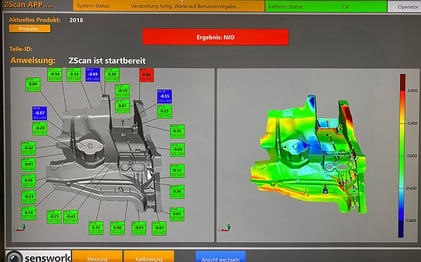

Evaluation with IO result and two alignment methods

Manual operation possible

Visualization of the machine condition

Typical scan volume (L x D x H): 1.500 x 700 x 500 mm

Lateral and radial runout <5 μm on 2 m length

Measuring head with up to eight 3D laser scanners

Visualization of the 3D measurement data on a 4K screen

For large parts

Evaluation with IO result and two alignment methods

Manual operation possible

Visualization of the machine condition

Typical scan volume (L x D x H): 1.500 x 700 x 500 mm

Lateral and radial runout <5 μm on 2 m length

Measuring head with up to eight 3D laser scanners

Visualization of the 3D measurement data on a 4K screen

| ZScan® S | ZScan® M | ZScan® L | |

|---|---|---|---|

| Resolution Z | 23 µm | 49 µm | 87 µm |

|

Scan volume X = Axis direction, Y = Depth, Z = Height |

X (max): 2,000 mm Y: 300 mm Z: 200 mm |

X (max): 3,000 mm Y: 700 mm Z: 500 mm |

X (max): 6,000 mm Y: 1,000 mm Z: 1,000 mm |

| Resolution Y | 60 µm | 134 µm | 205 µm |

| Resolution X |

Dependent on scan time Typically: 0.2 mm |

Dependent on scan time Typically: 0.2 mm |

Dependent on scan time Typically: 0.2 mm |

Download more information

No specialized personnel required

Easy to useNot the trained measuring technician, but a production employee operates ZScan® after a short briefing. This frees up capacities in the measuring room.

Simple control system

Intuitive FunctionsZScan® is controlled by simply pressing a start button. Thanks to the false-color image, the evaluation is clear and can be recorded quickly.

Intuitive & simple

Fast Parts ChangeoverEvery employee can change parts quickly and easily after a brief instruction: Thanks to the low demands placed on the part fixture, a setup process often takes only a few minutes.

Recognizing Trends in Time

Production ControlWith ZScan® you consistently keep track of your product quality. Deviations are detected in real time and enable immediate correction of production parameters.

Large and complex parts such as die-cast aluminum parts are usually inspected by experienced metrologists in a separate measuring room. With ZScan® this is much faster and easier.

Scarce resources in the measuring room can be saved with ZScan® , with an equally valid result and even more verifiable measuring points. The large amount of time required for manual inspection is eliminated in comparison to a complete inspection of the part within seconds. ZScan® overcomes the previously high time offset from part removal to the determination of the measurement data. Product adjustments or corrections are made directly in the production cycle with the innovative 3D measuring system. In addition, due to the brevity of the measurement and inspection, every component can be inspected. And all this directly in production, directly on or in line.

.png?width=709&height=441&name=Wei%C3%9F%20Schwarz%20Grau%20Handgezeichnet%20Linien%20Erkl%C3%A4rer%20Bildungsvideo(2).png)

.png?width=709&height=441&name=Wei%C3%9F%20Schwarz%20Grau%20Handgezeichnet%20Linien%20Erkl%C3%A4rer%20Bildungsvideo(3).png)

A system for 3D measurement uses laser triangulation to ensure the dimensional accuracy and squareness of clay bricks.

The ZScan 3D scanner from senswork supports the volume determination of food products on the conveyor belt.

Quality assurance in the automotive industry: Learn how senswork measures large aluminum assemblies and matches them with CAD file data.

Success Story | Magna BDW | Aluminum Die Casting

Find out more about the impressive features of ZScan® and how the 3D measurement system is performing after one year in production at Magna in our technical article:

Rocco Hahn

Head of Project Management at Magna

Very beneficial is the possibility to digitize parts ad hoc and to compare data sets with each other.“

Rocco Hahn

Head of Project Management at Magna

Rainer Obergrussberger

CEO

Business Development

senswork GmbH

Gewerbepark Lindach D 3

84489 Burghausen

Contact us.