Quality assurance in the automotive industry

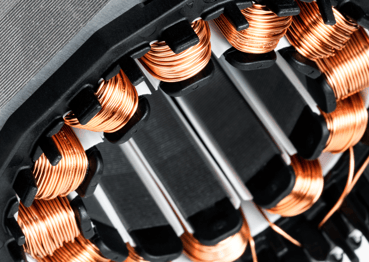

3D Measurement of Stators

Measuring and testing in seconds

For use directly in the production

Quality assurance in the automotive industry

3D Measurement of Stators

Quality assurance in the automotive industry

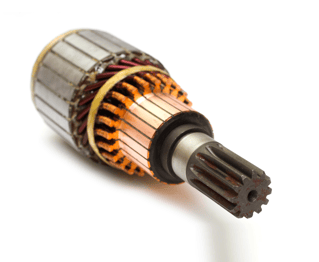

3D Measurement of Rotors

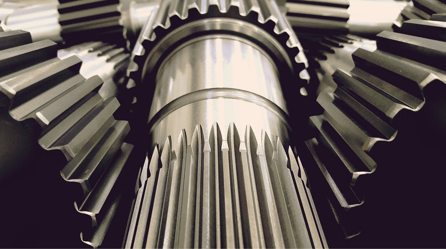

Quality Assurance in Power Transmission Engineering

3D Measurement of Gears

100% control for laser welding of hairpins

Inline measuring system for the production of stators or other rotationally symmetrical parts

The AI-based image processing system enables the modeling of complex relationships that cannot be fully described by rules. ZScan 360 captures high-resolution data of the welding points and evaluates them using Deep Learning.

The 3D Scanner detects deviations from the optimum weld seam characteristics. This allows conclusions to be drawn about upstream process steps. With AI-supported defect inspection in 3D, the quality of the laser welding process can be guaranteed and laser welding can be automated efficiently at the same time.

Rainer Obergrussberger

CEO

Business Development

senswork GmbH

Gewerbepark Lindach D 3

84489 Burghausen

Contact us: You can call us or leave a message